01 Import of Raw Materials

It is considered that the base of a manufacturing industry lies in its raw materials. Since the inception, plywood makers, realised the importance of best quality raw material-importing from the international market. Hindustan Plywood is the company that imports high-grade timber from the foreign markets and we at Hindustan Ply, obtain the raw materials from them for the manufacturing of plywood. Simply put, we are involved in the production and marketing of the plywood products within India.

02 Skilled Manpower

With a skilled and flexible workforce, Hindustan Ply has been able to successfully establish a brand name in the market. They have been playing a crucial role in the prosperity of our company. Highly trained and competent, they work in a clean and healthy atmosphere with an unwavering resolve to contribute in a meaningful way. Identifying the importance of teamwork, they work relentlessly to accomplish the goal of being recognised as one of the leading plywood manufacturers.

03 Research & Development

Our team works with immense enthusiasm and passion for bringing advancement in plywood production with the help of latest technology, adequate resources and the best manufacturing techniques in addition to rigorous R&D. Furthermore, our well-equipped modern laboratory for Research and Development assures a smooth flow of production and scope for the development of new products.

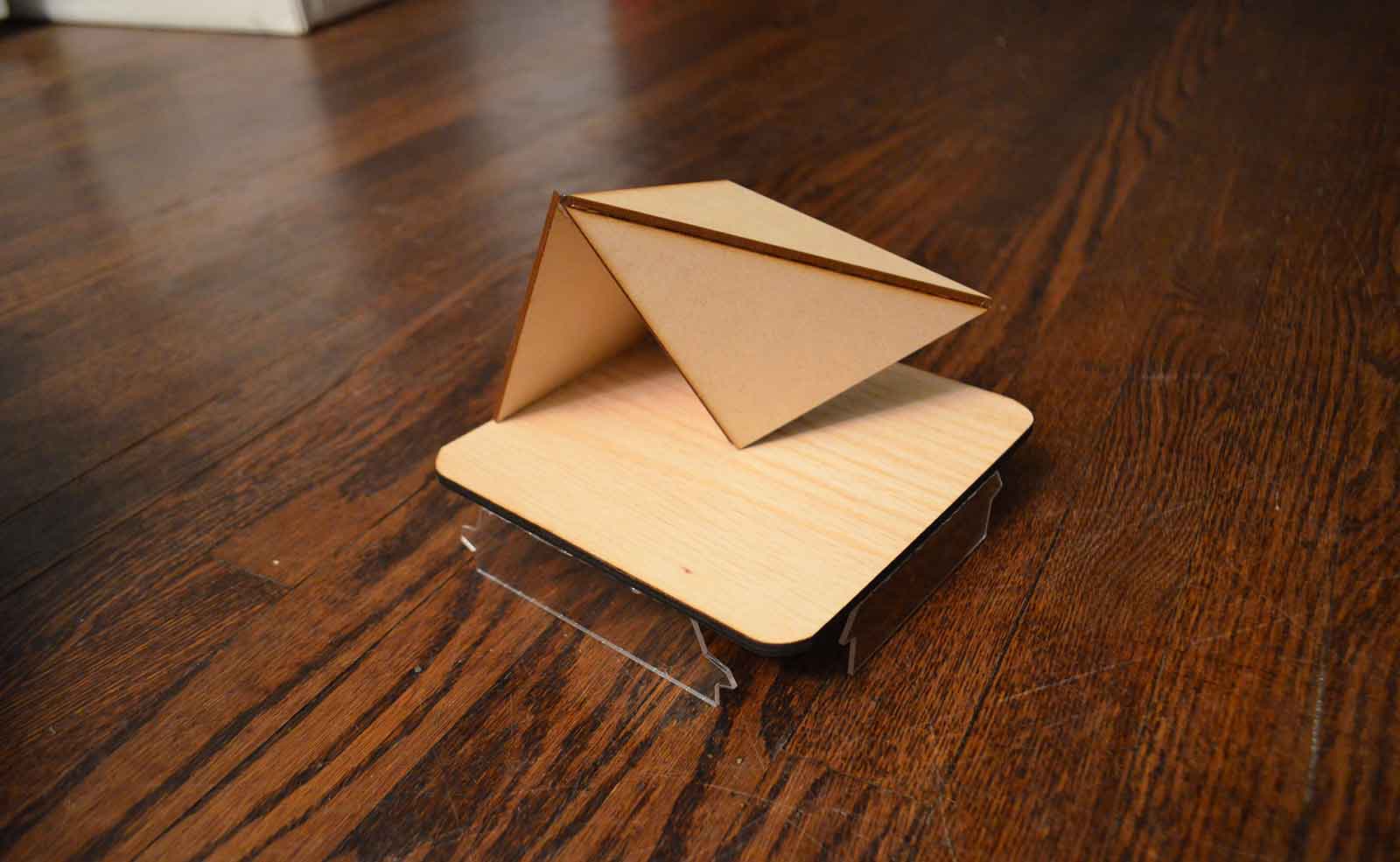

04 contruct

The veneer is glued along the edges to form larger sheets of the veneer for use in plywood production. Largesheets are then applied with an adhesive and stacked. On the outerlayers, the grain runs the length of the sheet. The grain of the individualsheets alternates on the interior. The larger glued sheets are then runthrough a press (most of which are heated) to dry the glue. Finally, thewood is subsequently trimmed, sanded if and as necessary and gradedfor quality.